In power transmission and distribution systems, the electrical transformer box (referred to as ^transformer box ̄) is widely used as an efficient and flexible power transformation device in urban construction, rural power grid renovation, industrial production, and other fields. This article comprehensively analyzes the basic knowledge of electrical transformer boxes, including their definition, classification, core advantages, ventilation design, and applicable scenarios, helping you gain an in-depth understanding of this ^power hub ̄.Electrical Transformer Box (11)in fact power transformer Our related products were once praised by users, which is the best self-affirmation of the products. https://www.jslhtf.com/

What is an Electrical Transformer Box? ! Definition and Development History

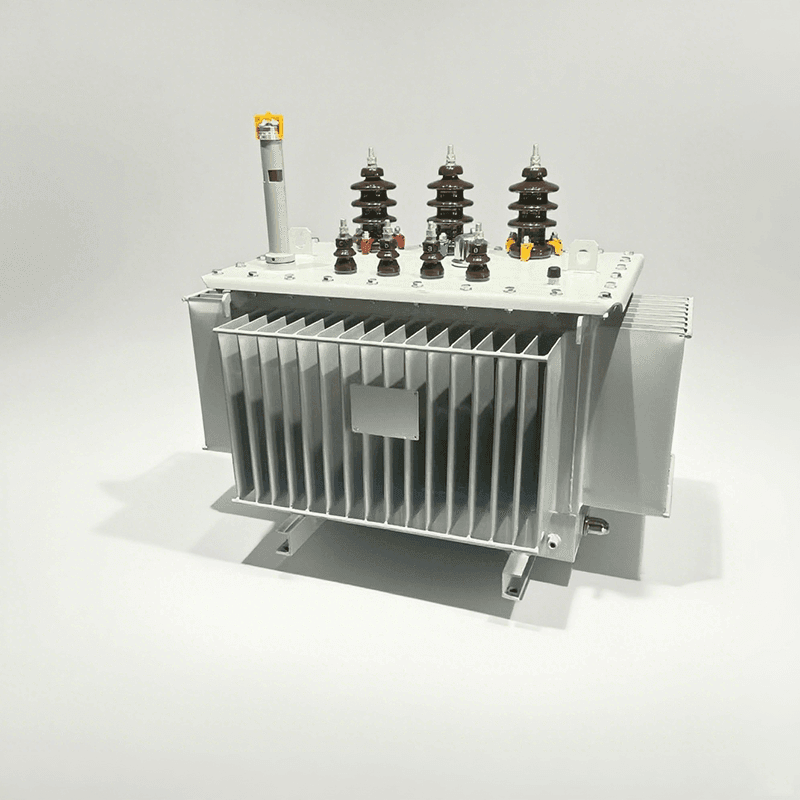

An electrical transformer box, also known as an outdoor complete set substation, is often referred to as a combined substation or prefabricated substation. It is an outdoor complete set of power transformation equipment that integrates high-voltage switchgear, distribution transformers, and low-voltage distribution devices through specific wiring schemes.

Its origin can be traced back to the 1960s-1970s in developed countries in Europe and America. Due to its significant advantages, such as flexible combination, convenient transportation, efficient installation, short construction period, low operating cost, no pollution, and maintenance-free operation, it quickly attracted attention from the global power industry.

In China, the development of electrical transformer boxes began in the mid-1990s, initially with simple products and a limited application scope. By the end of the 1990s, with the full launch of rural power grid renovation projects, the research, development, manufacturing, and application of electrical transformer boxes entered a period of rapid growth. Today, they have become core equipment for the construction and renovation of 10~110kV small and medium-sized substations (distribution stations), factories, mines, and mobile operation substations. Because they can penetrate into load centers, shorten power supply radii, and improve terminal voltage quality, they are regarded as the mainstream construction mode of substations in the 21st century.

Classification of Electrical Transformer Boxes: Choose According to Needs from Appearance to Structure

Electrical transformer boxes can be classified in various ways, including by appearance, material, and structural form. Different types are suitable for different scenarios to meet diverse needs.

Classification by Appearance and Shell Material

Landscape-style shell electrical transformer box

Wooden strip type: It has strong sun resistance and low thermal conductivity, which can effectively reduce the operating temperature of internal equipment; it is frost-resistant, corrosion-resistant, and rust-free, requiring no frequent maintenance and having a long service life; it has excellent moisture resistance, which can avoid condensation caused by temperature differences.Electrical Transformer Box (3)

Stone type: It has outstanding flame-retardant and fire resistance performance. Its shape and color can be customized according to the surrounding environment, combining functionality and decoration to harmoniously integrate with the environment.

Electrical Transformer Box (4)

Ordinary iron-shell electrical transformer box:

It has good flame retardant and fire resistance performance, high mechanical strength, and strong impact resistance, suitable for industrial or outdoor scenarios with low requirements for appearance.

Electrical Transformer Box (5)

Customized appearance electrical transformer box:

Its shape and color can be completely designed according to user needs and the surrounding environment. It can not only meet the power function requirements but also play a role in beautifying the environment, and is often used in urban landscape areas, residential areas, and other places with high requirements for aesthetics.

Electrical Transformer Box (6)

Classification by Structural Form

American-style electrical transformer box (combined substation)

Classified by oil tank structure into common tank type and separate tank type.

Advantages: Small size, small floor area, easy to install and disguise, and easy to coordinate with the community environment; it can shorten the length of low-voltage cables, reduce line losses, and power supply supporting costs.

Disadvantages: Relatively low power supply reliability; no electric mechanism, making it difficult to add distribution automation devices; lack of capacitor devices, which is unfavorable for reducing line losses; capacity increase requires rebuilding civil engineering foundations, which may lead to long power outages and increase project difficulty.

Applicable scenarios: Multi-story residential buildings, non-important buildings, etc., with low power supply requirements. When matched with a small ring network switch station, it can meet the basic power supply needs of multi-story residential buildings.

Electrical Transformer Box (7)

European-style electrical transformer box (prefabricated substation)

Mainly adopts ring network and terminal designs.

Advantages: Lower radiation than American-style electrical transformer boxes (the transformer is placed in a metal box with a shielding effect); can be equipped with a distribution automation system while retaining the core advantages of American-style electrical transformer boxes.

Disadvantages: Larger volume, slightly poor installation flexibility, which may have a certain impact on the layout of the community environment.

Applicable scenarios: Multi-story residential buildings, small high-rises, high-rise buildings, and important buildings with high requirements for power supply reliability.Electrical Transformer Box (8)

Core Advantages of Electrical Transformer Boxes: Why Become a New Favorite in Power Systems?

The rapid popularization of electrical transformer boxes in the power industry is inseparable from their many outstanding advantages, as follows:

Advanced technology, safe and reliable

The box body adopts leading domestic technology. The shell is mostly made of aluminum-zinc plated steel sheet, and the frame draws on standard container materials and production technology, with excellent anti-corrosion performance, ensuring no rust for 20 years; the inner sealing plate is an aluminum alloy gusset plate, and the interlayer is filled with fireproof and thermal insulation materials; the box is equipped with air conditioning and dehumidification devices, which can operate stably in harsh environments of -40≧~+40≧, unaffected by natural climate and external pollution.

High degree of automation, suitable for unattended operation

It can real-time monitor and control the temperature (0~99≧) and humidity (0~99% RH) in the box, and has remote smoke alarm and condensation (60% RH~99% RH) monitoring functions, meeting the needs of unattended operation; according to actual needs, it can also upgrade the image remote monitoring system to improve operation and maintenance efficiency.

Factory prefabrication shortens the construction period

In the design stage, only the primary main wiring diagram and the external equipment scheme need to be determined to select the standardized electrical transformer box specifications; all equipment is installed and debugged in the factory, realizing ^substation construction industrialization ̄. On-site installation only requires simple procedures such as box positioning, cable connection, and protection setting verification. It takes only 5~8 days from installation to commissioning, greatly shortening the construction period.

Flexible combination methods, adapting to multiple scenarios

The electrical transformer box has a compact structure, and each box can form an independent system with flexible combination modes: it can adopt a full-box design (35kV and 10kV equipment are built-in) or only configure a 10kV switch box (35kV equipment is installed outdoors). This flexibility makes it particularly suitable for the upgrading of old stations in rural power grid renovation. It can realize unattended operation by only adding a 10kV switch box without modifying the original 35kV equipment.

Electrical Transformer Box (13)

Cost-saving investment, quick results, and significant economic benefits