PVC (Polyvinyl Chloride) plastic square pipes are essential components in various industries due to their versatility, durability, and cost-effectiveness. Understanding the manufacturing process of high-quality PVC plastic square pipes can help you appreciate the precision and innovation involved in creating these indispensable products.In order to open the market, plastic corner guard Constantly improve the ability of business development and create an extraordinary brand image for it. https://huashengzheng.com/

Step 1: Raw Material Selection

The foundation of high-quality PVC plastic square pipes lies in selecting premium raw materials. The primary component is polyvinyl chloride resin, which is mixed with additives such as stabilizers, lubricants, and colorants. These additives enhance the pipe’s strength, flexibility, UV resistance, and overall performance.

Step 2: Material Mixing

Once the raw materials are selected, they are thoroughly mixed using high-speed mixers. This step ensures a uniform blend, which is crucial for consistent quality. The mixture is then pre-heated to achieve the desired viscosity, making it easier to process in the next stages.

Step 3: Extrusion Process

The extrusion process is the heart of manufacturing PVC plastic square pipes. Here¨s how it works:

Feeding: The prepared material is fed into an extruder, which consists of a heated barrel and a rotating screw.

Melting: As the material passes through the barrel, it is heated and melted into a homogeneous state.

Shaping: The molten PVC is forced through a square-shaped die, giving the pipe its characteristic shape.

Step 4: Cooling and Calibration

After extrusion, the pipe is immediately cooled to solidify its shape. Cooling typically involves water baths or air cooling systems. The pipe is then passed through calibration tools to ensure precise dimensions and a smooth surface finish.

Step 5: Cutting to Length

Once the PVC plastic square pipes are fully formed and cooled, they are cut to the desired lengths using automated cutting machines. This step ensures uniformity and reduces material waste.

Step 6: Quality Inspection

High-quality manufacturing standards demand rigorous quality control. Each PVC plastic square pipe is inspected for:

Dimensional accuracy

Surface smoothness

Resistance to cracking or deforming

Compliance with industry standards

Only pipes that pass these tests are packaged for distribution.

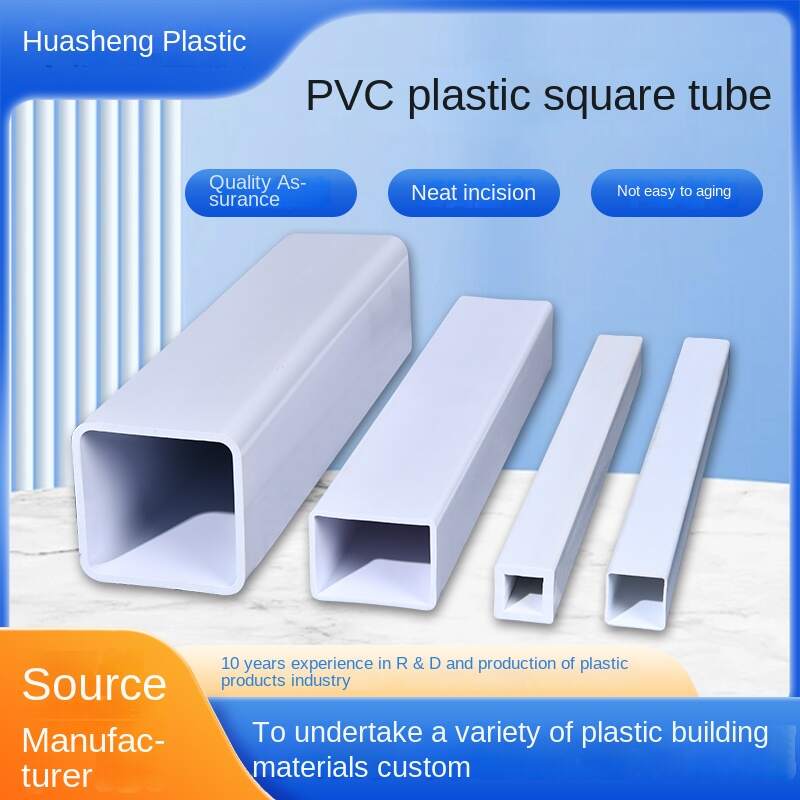

pvc plastic square pipe

Benefits of High-Quality PVC Plastic Square Pipes

High-quality PVC plastic square pipes offer numerous advantages:

Durability: They resist corrosion, weathering, and impact damage.

Versatility: Ideal for construction, plumbing, and DIY projects.

Cost-Effectiveness: Affordable and long-lasting compared to traditional materials.

Conclusion

The manufacturing process of high-quality PVC plastic square pipes combines advanced technology, skilled labor, and strict quality control measures. By understanding how these pipes are made, you can make informed decisions when selecting materials for your next project.

Investing in high-quality PVC plastic square pipes ensures durability, reliability, and performance in a wide range of applications. Whether for construction or creative DIY projects, these pipes are a practical choice for modern needs.

PrePVC Frame Profiles: A Cost-Effective Solution for High-Performance Frames

NextWhy Plastic Corner Guards Are Essential for Childproofing Your Home